Key Takeaways

- Predictive maintenance is transforming efficiency and risk management for critical industries worldwide.

- Data-driven insights and emerging technologies are driving new levels of operational reliability.

- Real-world examples highlight significant cost savings and reduced downtime for leading organizations.

- Challenges include integration with legacy systems and workforce adaptability.

- Continuous advancements are expected to accelerate predictive capabilities in the coming years.

The Shift from Reactive to Predictive Approaches

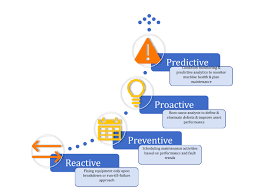

For decades, industrial organizations operated in a reactive mode: maintenance teams rushed to fix failed machinery only after a breakdown occurred. These unplanned outages drove up repair costs, caused dangerous workplace conditions, and left revenue on the table due to extended downtime. As competition and the complexity of industrial systems have intensified, more innovative solutions that maximize productivity and asset lifespan have become necessary.

The evolution toward predictive maintenance has emerged as the answer. By leveraging data from connected sensors and intelligent analytics, organizations anticipate failures before they result in costly shutdowns. Central to this revolution is APM software, which delivers asset performance management capabilities through robust data analysis, machine learning, and real-time alerts. These technologies enable organizations to move beyond guesswork and establish a proactive maintenance culture.

Key Technologies Driving Predictive Maintenance

Adopting predictive maintenance hinges on an innovative blend of sensors, the Industrial Internet of Things (IoT), and advanced analytics. Affordable and highly accurate IoT sensors are at the heart of this transformation, providing continuous asset health monitoring—from pumps and motors to complex infrastructure. Machine learning algorithms analyze these vast data streams, discerning subtle patterns that may indicate impending equipment failures. According to a Brookings Institution report, sensors’ falling cost and rising accuracy catalyze widespread adoption across sectors.

Cloud computing and digital integration allow these data streams to converge into actionable insights. Platforms aggregate information, visualize anomalies, and automatically trigger maintenance tasks when predefined thresholds are breached. This interconnected ecosystem has become essential for industries facing high stakes in safety, compliance, and operational efficiency.

The Role of Artificial Intelligence and Big Data

The sheer volume of sensor-generated data requires robust tools for analysis and decision-making. Artificial intelligence (AI) plays a pivotal role by powering predictive models that learn from historical equipment failures and real-time monitoring. These models grow smarter with each new data point—identifying normal wear, predicting component degradation, and optimizing replacement intervals. Industries such as utilities, manufacturing, and aviation have capitalized on these insights to streamline maintenance schedules and reduce operational risk.

The synergy of AI and big data reduces manual intervention and continuously improves prediction accuracy. Predictive analytics also play an essential part in regulatory compliance, safety initiatives, and long-term capital planning. Demand is spurring broader adoption globally as companies see quantifiable benefits from predictive maintenance. For additional insight, Forbes provides an overview of how AI’s role in maintenance is shifting industry standards (source).

Benefits of Predictive Maintenance for Industrial Assets

- Cost Reduction: Addressing minor issues before major breakdowns avoids expensive emergency repairs and minimizes unplanned downtime.

- Extended Equipment Lifespan: Scheduled, targeted interventions ensure machinery is serviced only when necessary, reducing unnecessary wear from routine overhauls.

- Safety Improvements: Preventing surprise failures lowers the risk of workplace accidents and environmental incidents.

- Optimized Resource Allocation: Maintenance teams can focus on tasks with the highest value, avoiding wasted effort on non-critical equipment.

Industry Success Stories

Predictive maintenance has already proven its value in diverse industries. Leading electric utilities, for instance, have reported reductions of unplanned outages by over 40% after implementing predictive models. These improvements lower operational and reputational risk, earning greater regulatory trust and customer satisfaction.

The aviation sector is another standout: major airlines routinely use predictive analytics to foresee engine issues, slashing mid-flight failure incidents and garnering significant cost savings. In the oil and gas industry, predictive maintenance tools have helped operators avoid environmental disasters and expensive fines while maintaining compliance more efficiently. The financial impact across these industries is tangible, as highlighted by The Wall Street Journal’s coverage of industry modernization efforts.

Challenges and Considerations

Transitioning to predictive maintenance isn’t without obstacles. Integrating modern predictive platforms with legacy systems often requires significant upfront investment and careful change management. Legacy machines may not accommodate sensors easily, and harmonizing data from different eras of equipment can be complex.

Workforce adaptability is another concern. Teams must learn to interpret data-driven insights, requiring new training programs and sometimes a cultural shift toward collaboration between IT, operations, and maintenance departments. The rapid pace of technology also demands ongoing professional development to stay ahead of emerging threats and opportunities.

Emerging Trends Shaping the Future

Predictive maintenance continues to evolve. Edge computing allows for faster, more local data analysis, reducing latency and ensuring that decisions are made closer to the assets. Digital twins—virtual replicas of physical assets—allow companies to simulate and optimize asset performance under various real-world scenarios. Machine Design highlights that these models enhance prediction accuracy and facilitate better risk management.

The democratization of predictive tools, driven by lower technology costs and intuitive software interfaces, is making predictive maintenance accessible to mid-sized and even smaller organizations. Ongoing advancements are set to integrate self-healing systems that can automatically remediate predicted issues, pushing reliability to unprecedented levels.

Practical Steps to Start the Journey

- Identify a high-value pilot project. Start with assets whose failure would have significant operational or financial consequences.

- Upgrade infrastructure with IoT sensors and ensure reliable, real-time data collection to build a solid foundation for analytics.

- Partner with analytics and data science experts to design and validate predictive models tailored to your asset base and operational needs.

- Foster collaboration among operations, IT, and maintenance teams to ensure buy-in and successful adoption of predictive practices.

Companies that embark on their predictive maintenance journey today position themselves to excel in an industrial environment defined by intense competition and operational complexity. They can reduce unplanned downtime, optimize equipment performance, and extend asset lifecycles by taking proactive steps. Success depends on adopting proven technologies that deliver reliable insights, implementing robust data strategies to ensure accuracy and scalability, and fostering organizational agility to adapt quickly to evolving demands. Together, these elements create a resilient framework for asset management, enabling businesses to protect their investments and sustain efficiency, innovation, and profitability well into the future.