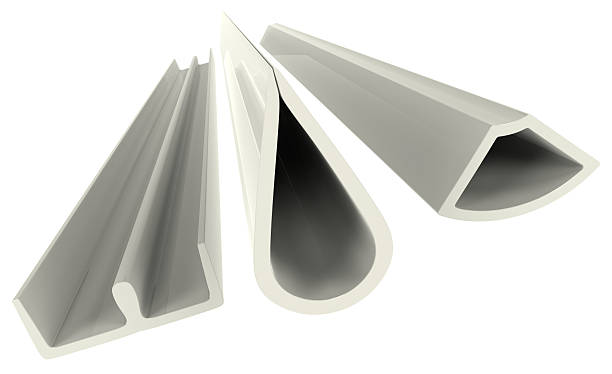

Rising raw material prices and growing demand for efficiency are pushing industries to seek smarter production methods. One solution that stands out is custom extruded plastic in India, which has become a preferred choice for manufacturers across construction, automotive, packaging, and consumer goods sectors. Unlike off-the-shelf plastic parts, custom profiles allow businesses to design exactly what they need while keeping costs under control. From reducing waste to improving durability, this process offers long-term savings that benefit both small-scale and large-scale projects.

Below, we explore seven ways custom extruded plastic profiles help businesses cut costs without sacrificing quality or performance.

1. Reduced Material Waste

In many industries, material wastage can account for up to 10–15 percent of total costs. With custom extrusion, profiles are shaped directly to requirement, which avoids unnecessary cutting and machining.

- Less wastage translates directly into savings

- Efficient use of raw material lowers production costs

- Reduces environmental impact through optimised resource use

👉 For example, a packaging company that previously machined plastic sheets into protective corners switched to custom extrusion. By eliminating trimming, they reduced scrap waste by 25 percent, saving both material and disposal costs.

2. Lower Tooling Costs

Tooling is often seen as a barrier to adopting custom processes, but extrusion requires far simpler dies compared to moulding techniques. This makes it accessible for businesses looking to experiment with new designs.

- Initial die costs are lower than injection moulding

- Easy to modify designs without high re-tooling expenses

- Ideal for both prototypes and mass production

👉 Many Indian extrusion manufacturers offer tooling at a fraction of international rates. A mid-sized furniture maker, for instance, commissioned a custom die for edge trims and recovered its tooling investment in less than six months through reduced labour and material savings.

3. Optimised Production for Bulk Orders

Scaling up with extrusion is highly cost-efficient. The more you produce, the lower your per-unit cost becomes. Bulk production not only ensures price stability but also guarantees uniformity across batches.

- Economies of scale reduce unit costs

- Consistent product dimensions lower rejection rates

- Easy repeatability for long-term projects

👉 For a detailed look, see 5 Cost Benefits of Using Custom Extruded Plastic in Bulk Orders.

4. Enhanced Durability and Reduced Maintenance

Durable components reduce repair and replacement expenses. With custom extrusion, profiles can be engineered with additives that match industry needs. This could mean stronger impact resistance for automotive trims or UV protection for outdoor cladding.

- Fewer replacements lower lifecycle costs

- Additives extend material life in harsh conditions

- Higher reliability builds brand reputation

👉 In one case, a construction supplier using standard PVC profiles switched to UV-stabilised extrusions. The profiles lasted nearly twice as long, cutting warranty claims and site maintenance expenses significantly.

5. Design Efficiency and Integration

Combining multiple functions into a single extrusion is one of its biggest strengths. This streamlines assembly, reduces parts inventory, and shortens production timelines.

- Snap-fit joints eliminate screws or adhesives

- Built-in channels allow for wiring or sealing

- Surface textures can be included directly during extrusion

👉 A lighting equipment manufacturer integrated wire channels directly into their extruded housings, removing the need for extra fixtures. This reduced assembly time by 30 percent and labour costs by almost 20 percent.

6. Lightweight Alternatives to Traditional Materials

Weight has a direct link to costs in industries like logistics and automotive. Custom plastic extrusion provides strong yet lightweight solutions that outperform metal or wood in many applications.

- Reduced transport costs due to lighter shipments

- Easier handling during installation saves labour

- Improved fuel efficiency in vehicles and equipment

👉 For example, replacing aluminium trims with extruded plastic in truck interiors cut overall vehicle weight by 15 kilograms. This small change translated to noticeable fuel savings over long-distance haulage.

7. Long-Term Supply Chain Savings

Supply chain stability is crucial for manufacturers. Working with reliable extrusion partners ensures uninterrupted supply of identical profiles, avoiding costly delays.

- Stable pricing over long contracts

- Predictable delivery schedules

- Reduced risks of inconsistent parts

👉 Several Indian manufacturers maintain in-house compounding facilities, allowing them to guarantee colour, strength, and dimensions batch after batch. This consistency reduces inspection costs and helps projects stay on schedule.

Why These Savings Matter

When businesses combine material efficiency, reduced tooling, and bulk production advantages, the savings are significant. Beyond direct cost reduction, companies also benefit from improved sustainability, faster project timelines, and lower risks of unexpected downtime.

Custom extruded plastic in India offers more than just affordability. It is a way for manufacturers to design smarter, scale production confidently, and achieve long-term profitability without compromising quality.

FAQs on Custom Extruded Plastic

Q1. What are custom extruded plastic profiles used for?

They are used in construction, automotive, packaging, consumer goods, and industrial applications. Examples include window frames, cable ducts, trims, cladding, and protective housings.

Q2. Why is custom extruded plastic in India cost-effective?

India offers cost benefits due to affordable tooling, bulk production capability, and access to quality raw materials. Manufacturers also provide flexible customisation, reducing the need for secondary processes.

Q3. Can extruded plastic profiles be customised for strength and durability?

Yes. Additives such as UV stabilisers, flame retardants, or impact modifiers can be integrated during extrusion, making profiles stronger and more suitable for specific applications.

Q4. How does custom extrusion reduce waste?

Unlike machining, extrusion shapes material directly into the desired profile. This minimises offcuts and scrap, saving raw material costs while improving sustainability.

Q5. Is custom extrusion suitable for bulk manufacturing?

Absolutely. Custom extruded plastic is highly efficient for bulk production, reducing unit costs and ensuring consistent quality across large orders.

Conclusion

Cost savings are no longer limited to bulk orders or reduced material prices. With the flexibility of custom extrusion, companies can cut expenses in design, tooling, production, and long-term maintenance. By focusing on efficiency at every stage, custom extruded plastic profiles have become a smart investment for industries looking to balance quality and affordability.